It can automatically power up the chip, automatically clip FAC, automatically fine-tune coupling, automatically glue and solidify, and automatically save the customer's data to the customer's database.

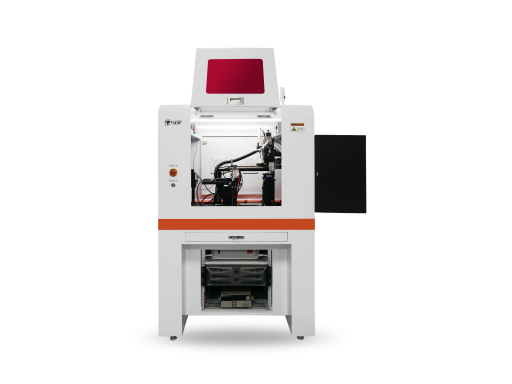

System characteristics 1.It can automatically power up the chip, automatically clip FAC, automatically fine-tune coupling, automatically glue and solidify, and automatically save the customer's data to the customer's database. 2.The FAC clamps have a vacuum sensor, so if we don't get it, the FAC will shut down and alert us 3.Products compatible with a variety of products, the channel spacing and height can be arbitrarily adjusted Conventional Process Function 1. Continuous automatic coupling of all FAC products to at least one single product in a specified order according to process requirements and ensuring that the customer's chips are not touched while moving 2. Automatically adjust the position of the base, automatically put down the charge probe. Need to ensure repeated positioning accuracy, repeated moves, the probe can not be pressed into the product chip and gold wire, etc. Can not touch the place. 3. AUTOMATIC FAC storage location, automatic capture. Smoothly into the FAC coupling region. 4. After the chip is automatically powered up, the system automatically fine-tunes the FAC according to the parameters such as the size, width and position of the light shift displayed by the light shift plane. When the coupling does not meet the customer requirements of the Position Power and angle (customers can according to the different chip to set their own) , the program alarm prompt, and automatically stop coupling. 5. The charging process needs to be gradually increased from low current to rated current. 6. Automatic Power Cut (current set to 0) , automatic FAC lifting, automatic glue. 7. The glue needs to be on the FAC side and not in the light of the chip. 8. After UV curing, power the chip again after curing, to check the size and position of the light class after curing FAC. 9. Auto-lift the FAC, power off, auto-lift the probe. 10. Auto-adjusting the base position, auto-dropping the charge probe, auto-capturing the next FAC, auto-coupling the next FAC. Other functions 1. The automatic program can be stopped and started at any time to continue running. So that the customer needs to stop the program during the use of other operations. 2. You are free to choose a single light path for coupling, rather than just coupling in a certain order (from FAC1 to Fac-n) . So that customers in the use of the process need to Re-a light way FAC rework coupling. 3. In the event of failure, such as unable to absorb FAC, no current or short circuit, sensor bottoming, the program can alarm prompt, automatic stop, and give reference solutions. 4.The system contains a variety of modes, such as operator mode and engineer mode. Operator mode requires simple and intuitive interface, easy to operate; engineer mode requires complete functions and convenient debugging. Can Manually control each module, can easily combine product process modification procedures, can do a variety of sensor testing, dispensing testing, power testing. Table of main equipment configuration FAC automatic coupling system configuration table

| Serial number | Device (component) name | Quantity |

| 1 | Insulating clamp | 1 |

| 2 | Power-on control accessories (cylinders, other adjusting clamps, etc.) | 1 |

| 3 | High power constant current source | 1 |

| 4 | 200mm Long-stroke electric slide | 1 |

| 5 | 20mm Vertical lift platform | 1 |

| 6 | Base fixture | 1 |

| 7 | Other accessories (connectors and other adjusting fixtures, etc.) | 1 |

| 8 | Electrically controlled high precision 6-axis adjuster | 1 |

| 9 | FAC Clamps | 1 |

| 10 | Motor wire | 9 |

| 11 | HIGH-POWER CCD camera | 1 |

| 12 | Lens adjusting mechanism | 1 |

| 13 | Computer (including Monitor) | 1 |

| 14 | Motion Controller | 1 |

| 15 | 20WHigh-power Optical flight | 1 |

| 16 | Software | 1 |

| 17 | UV Light source | 1 |

| 18 | Glue Dispenser | 1 |

| 19 | Fixture and adjusting mechanism | 1 |

| 20 | FAC Bin Placing fixture | 2 |

| 21 | Outer Shield | 1 |

Equipment data

随机资料

|

Serial number |

Name |

Quantity |

|

1 |

Packing list |

1份 |

|

2 |

Instruction Manual |

2份 |

|

3 |

Certificate of conformity |

1份 |

Equipment main technical parameters

一, the whole set of system technical parameters

1. Total coupling time (from adjustment of base position to end of curing)120s

2. Coupling efficiency 95%

二, each sub-unit part technical parameter pedestal part one-dimensional electric slide travel 150 mm, resolution 0.2 um three,

三,alignment part, movement is stable, location is accurate. The customer shall provide the specification of the regulating rack or the test report of each index.

四,FAC fixture, holding steady, moderate strength, can not touch the reflection area of FAC

五, video part

1. Zoom up to 500 x

2. Flexible Lens Adjustment Mechanism

3. The image is clear and can be clearly observed in the process of absorbing and adjusting the coupling of the FAC fixture.

六,The control part can be combined with the process requirements of the product,

七,need customers to provide dispensing machine and curing machine, such as the use of information

八, other parts

1. The design and manufacture of the equipment should be advanced in mechanical structure, technological manufacture, control system, use safety and equipment design.

2. To ensure the normal use of equipment necessary standard configuration must be complete, matching, attached accessories, cables, tools and spare parts must be complete.