It can automatically power the chip, automatically absorb the mirror, automatically fine-tune the coupling, automatically glue and solidify, and automatically save the data to the customer's database

System characteristics

1.It can automatically power the chip, automatically absorb the mirror, automatically fine-tune the coupling, automatically glue and solidify, and automatically save the data to the customer's database

2.Mirror fixture with a vacuum sensor, can not get the mirror will automatically stop alarm

3.Equipment compatible with a variety of products, the channel spacing and height can be arbitrarily adjusted

4.All mirrors of a single product can be continuously and automatically coupled in the specified order according to the process requirements, and the damaged customer's optical fiber can not be touched during the moving process

5.Glue can be evenly distributed according to the shape and position of the bottom of the mirror, and the length of the straight line can be adjusted from 3-9mm

6.A certain optical path can be freely selected for coupling, rather than simply coupling in a certain order (from reflector 1 to reflector n) , so that customers need to re-coupling a certain optical path during use

7.In case of failure, such as the mirror can not be sucked, no current or short circuit, the sensor touch bottom, the program can alarm prompt, automatic stop, and give reference solutions.

Table of main equipment configuration

| Serial number | Device (component) name | Quantity |

| 1 | Insulating clamp | 1 |

| 2 | Power-on control accessories (cylinders, other adjusting clamps, etc.) | 1 |

| 3 | High power constant current source | 1 |

| 4 | 150mm Long-stroke electric slide | 1 |

| 5 | 8mm Vertical lift platform | 1 |

| 6 | Base fixture | 1 |

| 7 | Other accessories (connectors and other adjusting fixtures, etc.) | 1 |

| 8 | Electrically controlled high precision seven-axis regulating frame | 1 |

| 9 | Vacuum fixture for reflector | 1 |

| 10 | Motor wire | 9 |

| 11 | HIGH-POWER CCD camera | 1 |

| 12 | Lens adjusting mechanism | 1 |

| 13 | Computer (including Monitor) | 1 |

| 14 | Motion Controller | 1 |

| 15 | 20W high power optical flight | 1 |

| 16 | Software | 1 |

| 17 | UV light source | 1 |

| 18 | Glue Dispenser | 1 |

| 19 | Fixture and adjusting mechanism | 1 |

| 20 | Integrating sphere | 1 |

| 21 | Outer Shield | 1 |

Equipment data

随机资料

|

Serial number |

Name |

Quantity |

|

1 |

Packing list |

1份 |

|

2 |

Instruction Manual |

2份 |

|

3 |

Certificate of conformity |

1份 |

Main technical parameters of equipment

一、Full set of system technical parameters

1. Total time of coupling (from adjustment of base position to end of curing) 120s

2. Coupling efficiency 95%

二、Some technical parameters of each sub-unit

Base section

The stroke of one-dimensional electric slide is 300 mm, the resolution is 0.2 um

三、Alignment Part

The movement is stable and the positioning is accurate. The customer shall provide the specification of the regulating rack or the test report of each index.

四、Reflector fixture

Holding steady, moderate strength, can not touch the reflective area of the mirror

五、Video section

1. Zoom up to 500 times

2. Flexible Lens Adjustment Mechanism

3. The image is clear, and the process of absorbing and adjusting the mirror coupling can be clearly observed

六、Control section

Be able to combine the product process requirements to facilitate the change of procedures

七、Dispensing and curing parts

Need customers to provide dispensing machine and curing machine operation manual and other information

八、The rest of it

1. Mirror pre-placement fixture: The fixture and the main system independent, pre-placed mirrors (mirror placement is convenient) , and then together with the fixture installed to the main system, and fixture assembly and disassembly is convenient, a single system with more than two sets of fixture.

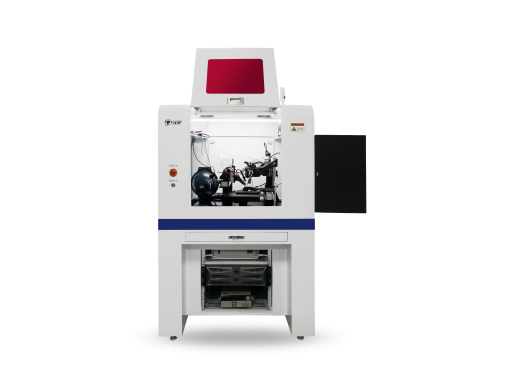

2. Outside protective cover: The whole system is placed inside the protective cover to prevent laser from causing harm to people. And does not affect the convenience of the system operation.